Introduction

In venture, the board, and quality control, the expression “PPM” holds huge significance. It remains an essential measurement for surveying and observing the quality and consistency of different cycles inside an association. What precisely does PPM depend on, and how can it affect organizations and enterprises? This article expects to dive into the full type of PPM, its applications across various areas, and its importance in guaranteeing effectiveness and greatness. Here we are talking about PPM: Everything About It.

We are discussing PPM: Everything About It:

Full Structure and Definition

PPM means “Parts Per Million.” It is a unit of estimation used to communicate the grouping of one substance inside another. In particular, it addresses the extent of parts of a specific substance for each 1,000,000 pieces of the all-out blend. PPM is generally utilized in different fields, including science, designing, producing, and ecological science, to measure the presence of pollutants, deserts, or other essential parts inside a more extensive framework.

Utilizations of PPM

1. Manufacturing Industry: In assembling, PPM fills in as a fundamental measurement for surveying item quality and consistency. By estimating the number of damaged parts or parts per million created, makers can recognize regions for development in their creation processes, limit squandering, and guarantee consistency with quality guidelines.

2. Environmental Monitoring: PPM is broadly utilized in ecological science and observing to gauge contamination fixations in air, water, soil, and other natural media. Checking PPM levels of poisons like weighty metals, synthetic compounds, and particulate matter assists controllers and natural organizations evaluate ecological quality, uphold guidelines, and alleviate dangers to general well-being and the environment.

3. Healthcare and Pharmaceuticals: In medical services and drug ventures, PPM is used to gauge the grouping of dynamic fixings, pollutants, or debasements in prescriptions, clinical gadgets, and medical services items. Keeping up with PPM levels inside adequate reaches is pivotal for guaranteeing the security, viability, and nature of drug items and clinical medicines.

4. Electronics and Semiconductor Manufacturing: In gadgets and semiconductor businesses, PPM measures deformities, contaminations, and blemishes in semiconductor materials, coordinated circuits, and electronic parts. Keeping up with low PPM levels is fundamental for boosting item yields, limiting creation costs, and guaranteeing the dependability and execution of electronic gadgets.

5. Food and Refreshment Industry: PPM is utilized in the food and drink industry to screen sanitation, quality, and consistency with administrative principles. By estimating PPM levels of pollutants, added substances, pesticides, and microbes in food items, makers can maintain food handling conventions, defend buyer wellbeing, and keep up with the trustworthiness of their items.

Meaning of PPM

1. Quality Assurance: PPM fills in as a basic device for quality confirmation and quality control in different enterprises. By observing PPM levels of imperfections, debasements, or foreign substances, associations can recognize deviations from quality principles, carry out therapeutic activities, and persistently work on their cycles to upgrade item quality and consumer loyalty.

2. Risk Management: PPM helps associations evaluate and relieve chances related to item quality, security, and administrative consistency. By checking PPM levels of basic boundaries and distinguishing expected wellsprings of fluctuation or disappointment, associations can proactively oversee gambles, forestall exorbitant reviews or liabilities, and maintain their standing and brand uprightness.

3. Process Optimization: PPM investigation empowers associations to advance their cycles, limit squandering, and amplify proficiency. By recognizing and tending to underlying drivers of imperfections or deviations, associations can smooth out their tasks, lessen creation costs, and accomplish more elevated levels of efficiency and seriousness.

4. Regulatory Compliance: PPM checking is essential in guaranteeing consistency with industry guidelines, principles, and determinations. By keeping up with PPM levels inside administrative cutoff points and adhering to quality necessities, associations can avoid fines, punishments, and legitimate liabilities and gain the trust and certainty of clients, controllers, and partners.

FAQs

What does PPM stand for?

PPM represents Parts Per Million. It is a unit of estimation used to communicate the centralization of one substance inside another, addressing the extent of parts of a specific substance for every 1,000,000 pieces of the all-out combination.

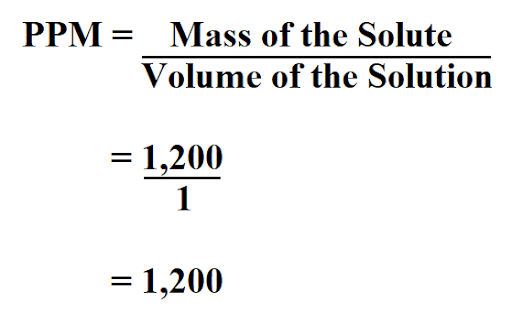

How is PPM calculated?

PPM is determined by separating the number of pieces of a substance by the complete number of parts in the blend and duplicating the outcome by 1,000,000. The equation for computing PPM will be PPM = (Portions of Substance/Absolute Parts) x a million.

What are a few typical uses of PPM?

PPM is utilized in different fields and enterprises, including production, ecological checking, medical care, hardware, and sanitation. It evaluates centralizations of pollutants, contaminations, dynamic fixings, or essential parts inside a more significant framework or combination.

How is PPM utilized in manufacturing?

In assembling, PPM is used to measure item quality and consistency. By estimating the number of faulty parts or parts per million delivered, makers can recognize regions for development in their creation processes, limit squandering, and guarantee consistency with quality guidelines.

Which job does PPM play in natural monitoring?

PPM is broadly utilized in natural science, and checking to quantify poison focuses on air, water, soil, and other ecological media. Checking PPM contamination levels assists controllers and biological organizations in evaluating ecological quality, authorizing guidelines, and relieving dangers to general well-being and environments.

How is PPM utilized in medical care and pharmaceuticals?

In medical care and drug ventures, PPM is utilized to quantify the convergence of dynamic fixings, pollutants, or debasements in prescriptions, clinical gadgets, and medical service items. Keeping up with PPM levels inside OK ranges is essential for guaranteeing the well-being, viability, and nature of drug items and clinical medicines.

Which job does PPM play in hardware and semiconductor manufacturing?

In gadgets and semiconductor enterprises, PPM measures deformities, debasements, and flaws in semiconductor materials, coordinated circuits, and electronic parts. Keeping up with low PPM levels is fundamental for augmenting item yields, limiting creation costs, and guaranteeing the unwavering quality and execution of electronic gadgets.

How does PPM add to food safety?

PPM is utilized in the food and refreshment industry to screen food handling and quality. By estimating PPM levels of toxins, added substances, pesticides, and microorganisms in food items, makers can maintain sanitation conventions, defend customer well-being, and keep up with the trustworthiness of their items.

What are OK PPM levels in various industries?

Satisfactory PPM levels differ depending on the application’s business, administrative principles, and explicit necessities. In certain businesses, for example, medical care and drugs, rigid quality principles might direct extremely low PPM levels. In contrast, in others, for example, natural checking, OK levels might shift given hazard evaluations and administrative rules.

How is PPM checked and controlled in industries?

PPM levels are observed and controlled using scientific procedures, instruments, and quality control measures. These may incorporate substance examination, spectroscopy, chromatography, sensor innovation, and measurable cycle control strategies to guarantee that PPM levels stay inside satisfactory cutoff points and fulfill quality guidelines.

Conclusion

PPM, or Parts Per Million, is a flexible and irreplaceable measurement utilized across different ventures to evaluate fixations, survey quality, and screen consistency with principles and guidelines. Whether in assembling, ecological observing, medical care, hardware, or sanitation, PPM guarantees effectiveness, greatness, and unwavering quality in cycles and items. As associations take a stab at consistent improvement and greatness, the significance of PPM as a device for quality confirmation, risk the board, and cycle streamlining will continue developing, driving advancement, supportability, and seriousness in the worldwide commercial center.